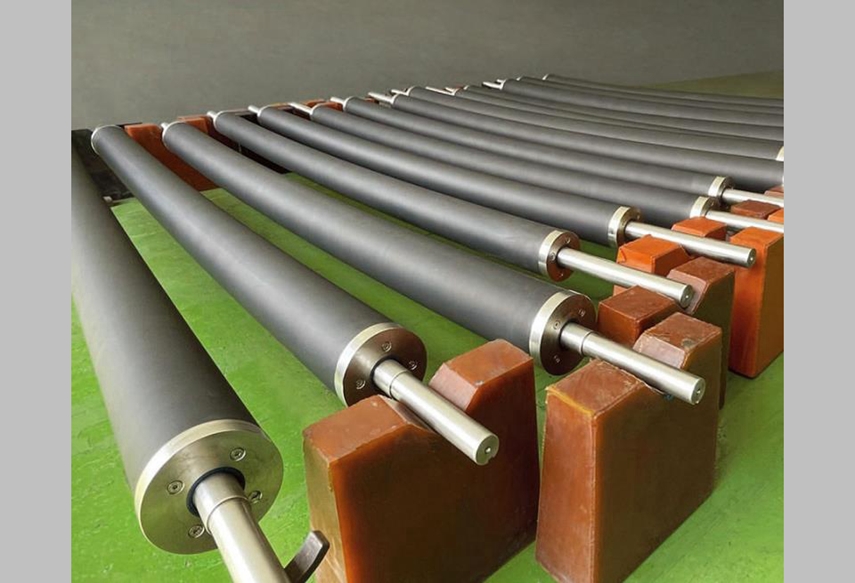

Filtex Cr

Filtex Cr

The Filtex CR rubber compound was specially designed for the second squeezer of the yarn sizing bath. This position requires the fulfillment of 2 simultaneous jobs: squeezing and applying size, both outstandingly achieved by our Filtex CR's porous surface

1. Squeezing: After the bath impregnation the yarn must be squeezed in order to eliminate the excess of size that has been absorbed. This is achieved by the pressure effect of the rollers on the yarn. The viscoelasticity of the FILTEX CR rubber and its unalterable hardness provide the correct pressure for an excellent squeezing without damaging the yarn.

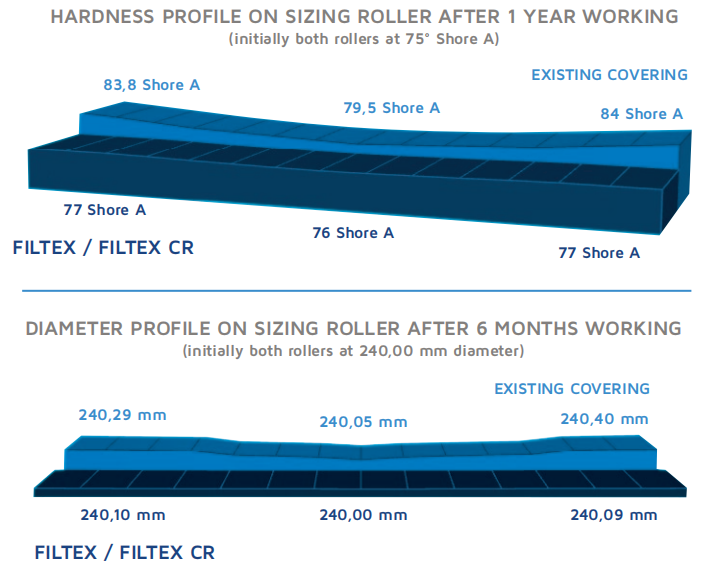

2. Size Contribution: In addition to the squeezing, this position must allow the yarn to absorb the necessary amount of size for a correct application, and this absorption must be obtained in a regular and homogeneous way all over the surface of the roller, avoiding excessive accumulation of sizing on the yarns. This is achieved by the porous surface of the FILTEX CR. The rubber mixture includes a specific filler which dispersion provides the unique combination of porous surface/ inorganic material that maintains a constant layer of size on the roller surface while it is working. This layer is reabsorbed by the yarns, achieving a controlled size application before entering the drier section.Measuring the hardness and the swelling on the ends of two rollers working under the same conditions on a yarn sizing machine, one covered with our FILTEX CR and another covered with another rubber, one can see how FILTEX CR keeps its hardness and surface diameter unaltered after several months of non stop work.